Five Advantages Of Products

- All of automatic assembly motions in entire machine are designed with continuous interlock function, the machine will alert & shutdown in an automatic way if any abnormal occurred;

- The Pneumatic component or parts are introduced with branded Air TAC,SMC ,Festo that enables the process more stable and accurate

- The branded Mitsubishi PLC , Skyworth or Winview HMI (human machine Interface) touch screen, Japan KEYENCE Optical Fiber are introduced.

- The machine frame employs electrostatic spraying & paint-drying processes with the purpose to anti-rust;

- .

Product Details

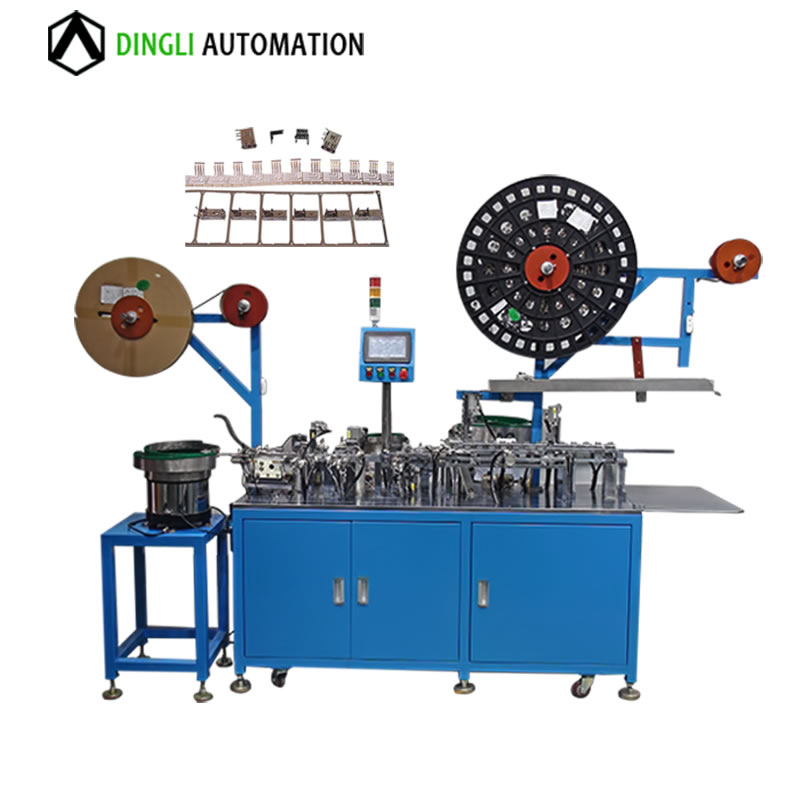

This automated USB connector assembly machine aim to provide an integral automation solution to assembly USB series connectors from components and parts loading, feeding, cutting,inserting, embedding, assembling, testing and unloading.Cam structure pin cutting device is designed with to achieve an excellent pin cutting result before insertion and embedding.

CCD Vision inspection has been developed into this automated RJ 11 connector embedding machine to perform an advanced vision measurement to sort the product assembled.

This automated RJ 11 connector embedding machine is designed with PLC & touch panel control system with an excellent control performance. Alerting system such as lack of parts and components or machine in operational troubleshoots can be indicator through a light tower or acoustic alarm.The HMI(Human-Machine-Interface) is mounted the branded touch panel with its brand such as winview or other famous brands, EN/CN operational menu can display the assembly operational status and functional button on the screen.

Assembly FlowAn integral assembly and embedding solution has been made to complete a series of assembly movements from loading, feeding, cutting, assembling, embedding, inspection, sorting and unloading.The pin in row of frame are loaded and fed through a proper mechanism of a tape-and-reel feeder;Plastic housing is designed to load and feed via a special designed vibratory bowl feeder with custom channel to convey and feed the plastic housing to a designated position;The pin in row will be cut through a special design cam type pin insertion mechanism to perform an accurate pin alignment and insertion.

Final product inspection will be implemented after the product complete the assembly operations with the main target to check if any shortage or missing of pins in the RJ 11 connector.An automatic sorting devices will work according to the signal based on the inspection result to sort the reject from accepts among the final products.

After sorting, the accepts will be unloaded automatically to package or other production lines.